Cheek plates are an important part of truck and trailer suspension systems, designed to provide stability, support, and correct alignment for moving components. They help ensure that suspension assemblies function smoothly under load, contributing to both safety and ride performance. Understanding where cheek plates are located and how they work can help operators maintain their vehicles more effectively.

Primary Function of Cheek Plates

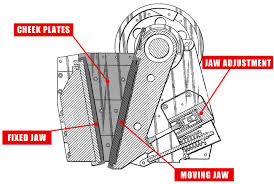

The main role of cheek plates is to provide a secure mounting surface for suspension components, such as torque arms, pivot bolts, and brackets. They help reinforce these mounting points, ensuring the suspension can handle heavy loads without shifting or wearing unevenly. Cheek plates also help distribute stress across the suspension assembly, reducing the risk of cracks or damage in the frame or mounting area.

Common Applications on Trucks

On trucks, cheek plates are typically found in the suspension framework, especially in areas that support torque arms or equaliser beams. They are used in both tandem and single-axle configurations to keep pivot points aligned and stable. By providing strong mounting positions, they help maintain proper suspension geometry under varying load conditions.

Common Applications on Trailers

In trailers, cheek plates are usually part of the bogie assembly and can be found in both air suspension and mechanical spring setups. They are strategically positioned to hold pivot bolts and other components in place, ensuring that the suspension can absorb shocks and maintain even weight distribution across the axles.

Variations in Cheek Plate Design

Cheek plates come in different configurations depending on the application. Some are designed as left-hand or right-hand versions, while others are symmetrical. They may vary in size, thickness, and hole layout to match specific suspension models. Material choice also plays a role, with mild steel used for standard applications and high-tensile steel for heavy-duty setups.

Signs It’s Time to Replace a Cheek Plate

- Cracks or fractures in the plate.

- Bending or distortion that affects component alignment.

- Excessive wear around bolt holes.

- Corrosion or thinning metal that reduces structural integrity.

Wrapping Up

Cheek plates are a vital link in both truck and trailer suspension systems, providing the stability and strength needed to handle heavy loads safely. Whether in the suspension framework of a truck or the bogie assembly of a trailer, keeping them in good condition helps maintain ride quality, safety, and compliance. Regular inspection and timely replacement are key to preventing costly downtime.